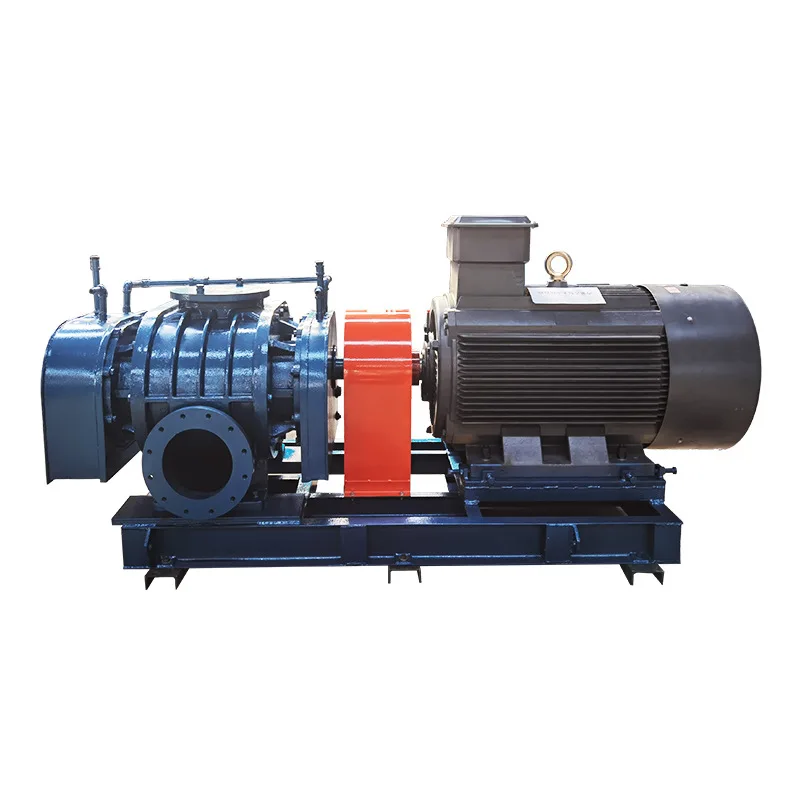

The Roots Blower in action with the Vacuum System

Roots blower vacuum systems are unique and amazing machines that operate by virtue of a special mechanism. Those systems use rotors, which turn in opposite directions to achieve high-speed airflow. Rotors have "lobes" in them that suck air from the inlet to the exit of the system. This creates a vacuum anywhere there is an opening in the device, making it invaluable for industrial applications that require materials to be moved or lifted through air pressure. Roots Blower Vacuum System is widely used in the field of chemical processing, food packaging system and also waste water treatment industry etc.

There are a number of roots blower vacuum technology suppliers operating within the market and these businesses provide an important function in supplying this cutting edge equipment. Gardner Denver, Atlas Copco and Tuthill Corporation are few of the prominent players that deal in manufacturing & distribution of vacuum pumps, blowers and compressors designed to cater different industrial areas. Recommended services might include Gardner Denver products for chemical processing, food and beverages, pharmaceuticals etc. Atlas Copco - Specializes in oil-injected rotary screw vacuum pumps used for packaging, automotive and other industrial processes. Whereas Tuthill Corporation concentrate on oil-free air handlingworking parts.

The good aspects of roots blower vacuum use in industrial processes do not end here and as a consequence they have been established broadly for so many applications. They are generally high-volume, low-differential blowers built to move material and elevate over long distances. In addition, its oilless nature allows it to reduce the risk of contamination from oils while slashing maintenance costs. Another advantage of roots blower vacuum systems is that they are easily installed and operated due to how simple their design ise.ArgumentParser Additionally, they are simple in design making them very quiet and thus a far more pleasant working environment. Finally, these systems are very reliable and can be maintained for longer periods without maintenance reducing the downtimes in between production processes.

In plain words, the roots blower vacuum systems require periodic maintenance for keeping its operation at best performance. The first part of maintenance is to simply keep the system clean and free of any debris that could harm the brake rotors. The filter, as well as the inlet and outlet have to be cleaned periodically while you check them for damages like cracks or leaks. Troubleshooting also involves checking the inlet and outlet pressure to ensure it is working efficiently, as well as determining any vacuum or pressure losses. Obstructions in the filter, inlet, and outlet should be handled immediately. Monitoring oil levels and the regularity of changes is also key because rotor damage can occur from low oil volume.

When it comes to deciding between roots blower vacuum system against other forms of technologies including liquid ring vacuum or screw vacuums, there are unique features present. Used in industries such as paper mills, chemical processing and power generation that employ a water seal to prevent air leakageLiquid ring vacuum systems are commonly used. But they have issues with water contamination and need regular renewal of water as well maintenance. Screw vacuum systems are oil-sealed and offer operating high-pressure differentials, so they work well for higher-vacuum duty points. However, they require regular oil changes and might take longer to start. Accordingly, roots blower vacuum systems provide an oil-free alternative which is also suitable for high air volumes and process applicability. With durability and very little required maintenance, they end up being a highly cost-effective alternative for even the most varied industrial processes.

The roots blower vacuum technology is therefore an important component in industry for efficient and reliable air conditioning. These systems can work non-stop in industrial installation and applications with simple maintenance, troubleshooting. As you can see, when compared to other vacuum systems this combination of an oil-free design and roots blower technology that allows any maintenance issues inherent in the system be performed simply with few operations brings a very convincing solution for these industries. As technology continues to advance, we can expect a wider range of improvements and developments in the field of roots blower vacuum systems which should only help offer an even better set of advantages for industrial processes.

three-blade Roots Blower is quieter has lower vibration compared to the two-blade Roots Blower. castings are cast with resin sand, and the impeller designed strictly in accordance with theory of involute, and then modelled in a computer that is a complete guarantee of the meshing roots blower vacuumof involute, and increases efficiency. exhaust intake ports have a spiral design and come with a muffler. This ensures that the intake and exhaust vibrations soft, the vibration is small and the noise low. The fan gear has been constructed of 20CrmnTi and has been carburized, and then ground to level 5 precision. tooth's surface has more resistance to wear and lowers the sound of the gear.

(1)More efficientTransmission and lubrication system coordination and structure are distinctive and can reduce losses.(2)Longer lifemain components are imported and unique design of the lubrication roots blower vacuumlets fan run effortlessly, safely and effectively with low failure rates longer run time.Conservation energy and protection of environmentdistinctive sealing system design ensures that air output is cleaner. scientific noise reduction structural design makes equipment less noisy; effectively reduces energy usage.

Every employee, from director all way to the worker are service providers who roots blower vacuumhighest quality and professional service. products undergo a rigorous, standardized inspection before leave the factory. If there issues with the product's quality, it will be replaced within year. Video guidance for debugging within 24 hours, you can visit the site of the project to identify any issues within 48 hours, and provide prompt solutions.

Shandong Jianyu Heavy Industry Co., Ltd. Blowers, Roots roots blower vacuumused in various industries, including melt-blown fabric well as aquaculture and sewage treatment, pneumatic transport, special gases and dust removal along petrochemicals and power cement. Roots blowers are manufactured in the US and manufactured and provide problem of strong. company is a leader in technical production development capabilities. It is company that combines development, research, manufacturing and sales. company's leading product, three-blade Roots blower is optimized designed absorbing both domestic as well as foreign Roots blower experience in design. There over ten models, and more than 100 specifications. It is easy to operate, compact but has a significant flow rate, and is low-noise. Smooth, virtually no noise in whole machine

Copyright © Shandong Jianyu Heavy Industry Co., Ltd. All Rights Reserved | Blog | Privacy Policy